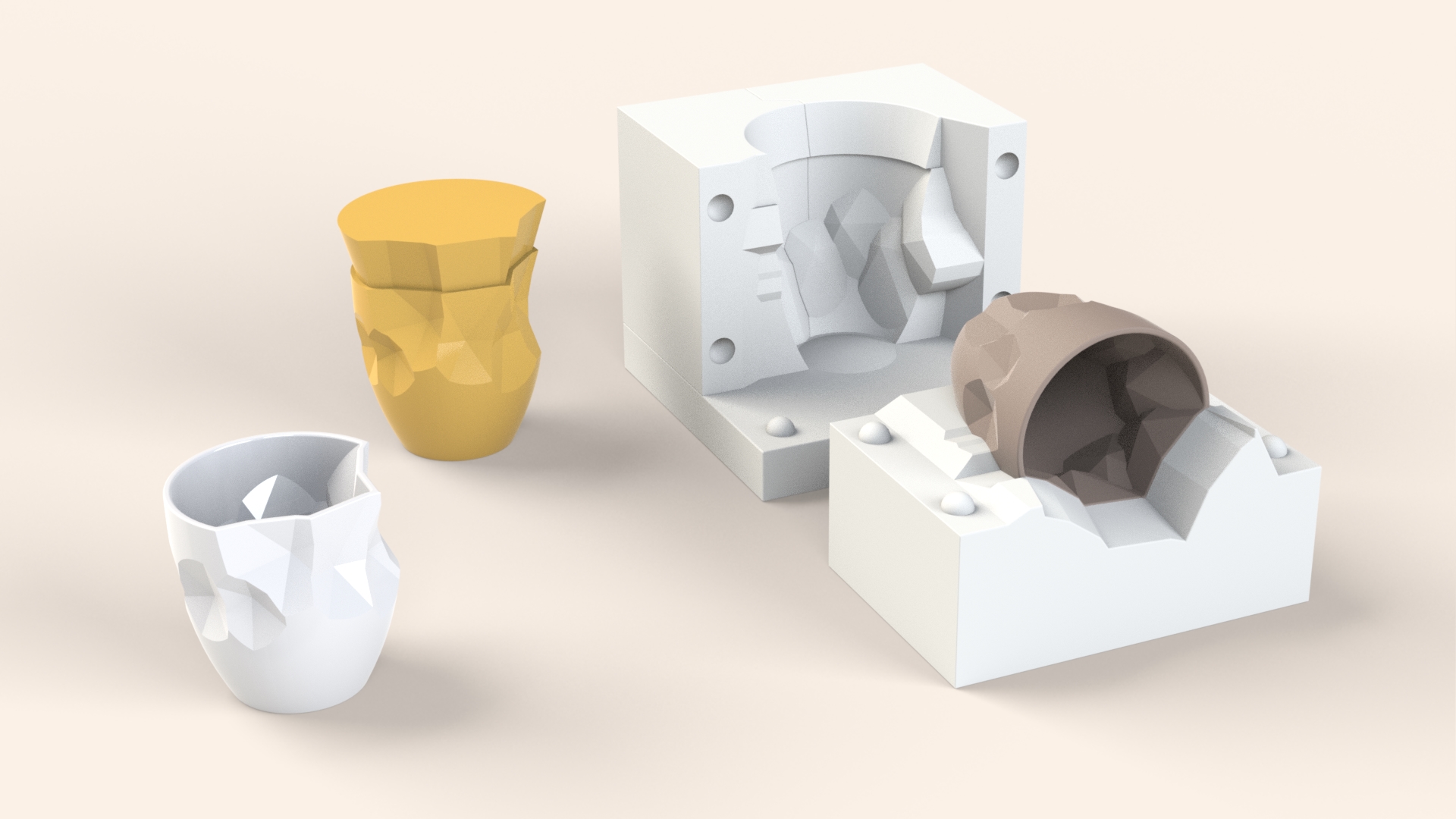

If you are looking for a better way to cast parts, shuttle molds might be the answer. Shuttle molds offer many advantages over traditional casting methods, and they are becoming more and more popular among plastic molding manufacturers. In this post, we will discuss the benefits of shuttle molds and explain how they work. We will also provide some tips on choosing the right shuttle mold for your needs.

Shuttle molds offer a number of advantages over traditional casting methods. First, shuttle molds are faster and more efficient. They can produce parts in a fraction of the time it would take to cast them using traditional methods. Second, shuttle molds are more precise. They allow for tighter tolerances and less waste. Third, shuttle molds are easier to use. They require less training and experience to operate, and they are less likely to break down or malfunction.

If you are considering switching to shuttle molds, there are a few things you should keep in mind. First, you will need to choose the right mold for your needs. There are many different types of shuttle molds on the market, so it is important to select one that is well-suited for your application. Second, you will need to train your employees on how to use the mold. Shuttle molds are not difficult to operate, but it is important that your employees are familiar with the process before they begin production. Finally, you will need to maintain your shuttle mold properly. Like any other piece of equipment, shuttle molds require regular maintenance and cleaning in order to function properly.

If you are looking for a better way to cast parts, shuttle molds might be the answer. With their many advantages over traditional casting methods, shuttle molds are becoming more and more popular among manufacturers. Keep the tips in this blog post in mind when considering switch to shuttle molds, and you will be on your way to a more efficient and productive casting process.

Shuttle molding is a type of plastic injection molding where the molten plastic is injected into the mold at high pressure. The molten plastic then cools and solidifies, taking the shape of the mold cavity. Shuttle molds offer many advantages over traditional injection molds, including increased speed, efficiency, and precision. They are also easier to use and require less training for employees. If you are considering switch to shuttle molds, keep the tips in this blog post in mind to ensure a smooth transition. Thanks for reading!

FAQs

What are the advantages of shuttle molds?

Shuttle molds offer many advantages over traditional casting methods, including increased speed, efficiency, and precision.

How do I choose the right shuttle mold for my needs?

Shuttle molds come in a range of shapes and sizes, so it’s critical to choose the right one for your application. You should also think about your employees’ training and experience before making a purchase.

How do I maintain my shuttle mold?

In order to function correctly, Shuttle molds need to be maintained and cleaned on a regular basis.